electronics

A decade ago, the electronics and semiconductor industry in Europe was considered by many to be on the brink of extinction. Now it is experiencing more than just a renaissance. This is based on a number of stable pillars that also have a very positive impact on the future development of the industry.

On the one hand, it is of course electromobility and the automotive sector in general that provide the crucial prerequisites for this change. Increasingly well-equipped base vehicles, extensive sensor technology, and autonomous driving would not be possible without corresponding innovations in modern electronic components. This trend also includes, for example, the ever-evolving smartphones, which are often purchased anew each year, the Internet of Things (IoT), and the ongoing digitalization.

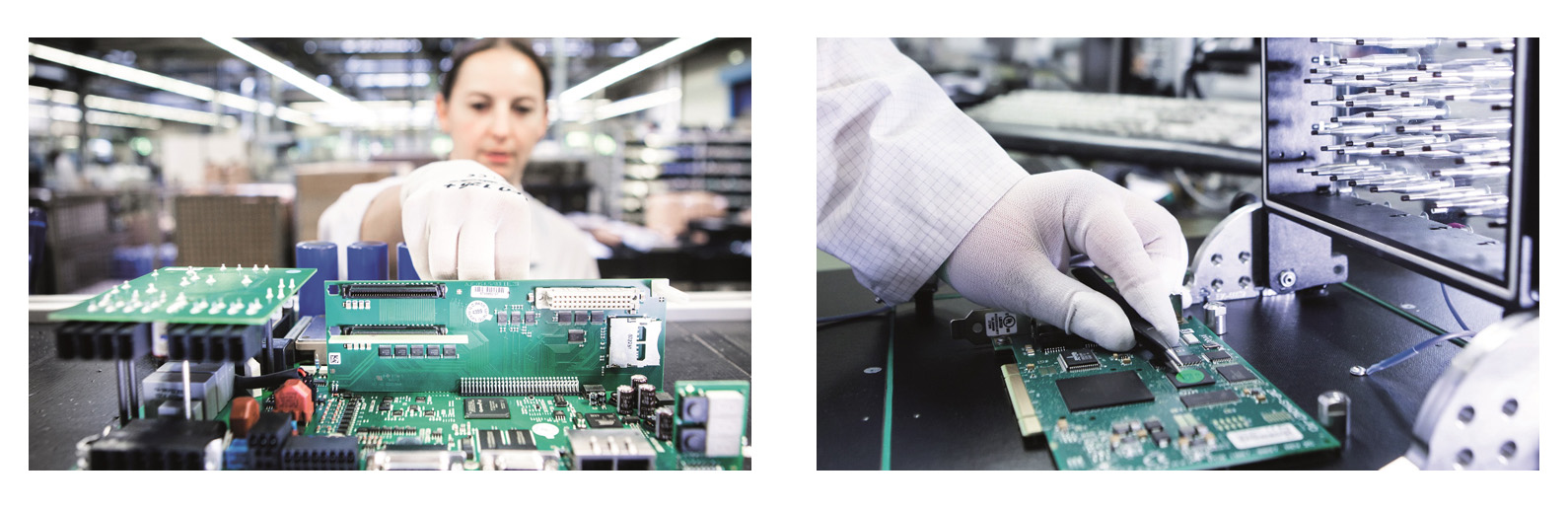

One problem that arises from this is the often associated increase in the complexity of value chains. These chains are currently often operating at capacity limits, are globally distributed, and thus increase the demands on planning and control. Challenging new project launches are no longer the exception, but have become the norm due to these requirements. These changes naturally affect the entire industry, but particularly companies in the electronics sector. The growth momentum is only being slowed by the increasingly noticeable international shortage of skilled workers.

Relocating machinery and equipment has become standard practice in the electronics industry. This is not only known to industry insiders; the process is becoming increasingly common outside the sector as well, and is seen as an integral part of the production and development process. As a result, machines, equipment, or even entire factories are being moved to various destinations in Europe and Asia. In some cases, these locations were previously considered exotic and not even considered as options. One of the most important challenges in this area is undoubtedly anticipating the massive cost and competitive pressures.

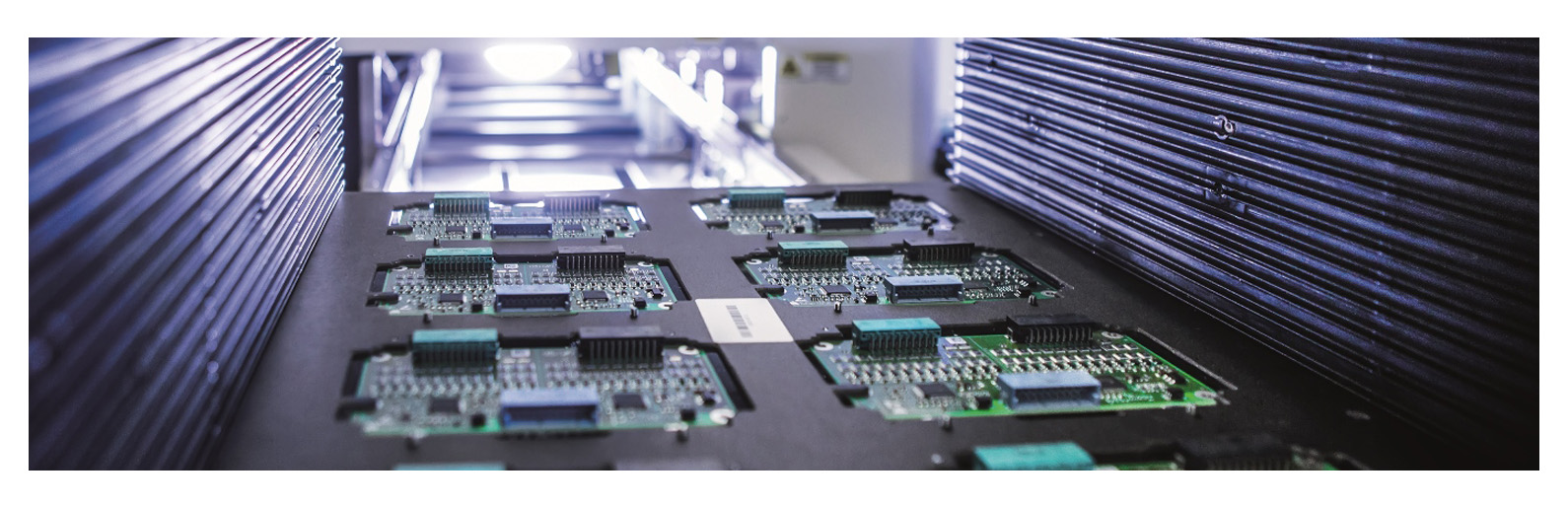

However, it is no longer sufficient to produce exclusively at the lowest-cost locations using equipment with a high degree of manual labor. Highly automated machines and equipment must also be included in relocation considerations to ensure a competitive, world-class production process.

The IQX Group is very familiar with these challenges facing the electronics and semiconductor industry and can support companies as project managers or on an interim basis in a wide variety of functions.